When it comes to finding the perfect lawn mower, you want to know that you’re investing in a reliable and trusted brand. That’s why the question of who builds Toro lawn mowers often comes up. Well, rest assured, as we’re about to unveil the answer! Toro lawn mowers are built by a company with a long and impressive history in the industry. With a commitment to innovation, durability, and performance, Toro has become a go-to choice for homeowners and professionals alike. So, let’s uncover the fascinating story behind the makers of Toro lawn mowers and discover why they’re a cut above the rest.

Toro Company Background

History of the Toro Company

The Toro Company is a renowned manufacturer of outdoor equipment and turf maintenance products. Established in 1914, the company has a rich history of innovation and excellence. It originally started as the Toro Motor Company, producing engines for the Bull Tractor Company. However, in 1917, Toro shifted its focus and began manufacturing tractor engines and truck engines. Over the years, the company diversified its product range to include lawn mowers, snow blowers, irrigation systems, and more.

Overview of Toro’s Operations

Today, Toro is a global leader in the industry, offering a comprehensive range of products designed to meet the needs of homeowners, professional contractors, and golf course managers alike. The company’s operations span across various segments, including residential, commercial, and professional markets. Toro is dedicated to providing high-quality products and exceptional customer service, making it a trusted name in the industry.

Toro’s Commitment to Quality

As a company, Toro is deeply committed to manufacturing products of the highest quality. They understand the importance of reliable and efficient equipment for their customers. From the design and engineering stages to the manufacturing and assembly processes, Toro employs stringent quality control measures to ensure that every product meets their rigorous standards. This commitment to quality is reflected in their products’ performance and durability, providing customers with long-lasting value and satisfaction.

Manufacturing Facilities

Types of Manufacturing Facilities

Toro operates a diverse range of manufacturing facilities to support its production needs. These facilities are equipped with state-of-the-art machinery and technology to ensure efficient and precise manufacturing processes. Toro has both in-house manufacturing capabilities, where they produce various components themselves, as well as external partnerships and collaborations for outsourced production.

Locations of Toro Manufacturing Facilities

Toro has several manufacturing facilities strategically located around the world. These facilities are spread across North America, Europe, and Asia, allowing Toro to serve customers on a global scale. Some notable locations include Bloomington, Minnesota; El Paso, Texas; Tomah, Wisconsin; and Windom, Minnesota. Each facility is strategically located to efficiently meet the demands of specific markets and regions.

Toro’s Approach to Manufacturing

Toro takes great pride in its manufacturing processes, which are centered around efficiency, precision, and innovation. The company leverages advanced technologies and automation to streamline production, ensuring consistent quality and timely delivery. Toro continuously invests in research and development to enhance their manufacturing capabilities, enabling them to stay at the forefront of the industry.

Toro Lawn Mower Models

Overview of Toro Lawn Mower Range

Toro offers a wide range of lawn mower models, catering to various needs and preferences. Their lineup includes residential, commercial, and professional-grade mowers, each designed to deliver exceptional performance and ease of use. Toro lawn mowers are known for their superior cutting performance, durability, and innovative features that make lawn care a breeze.

Key Features and Technologies

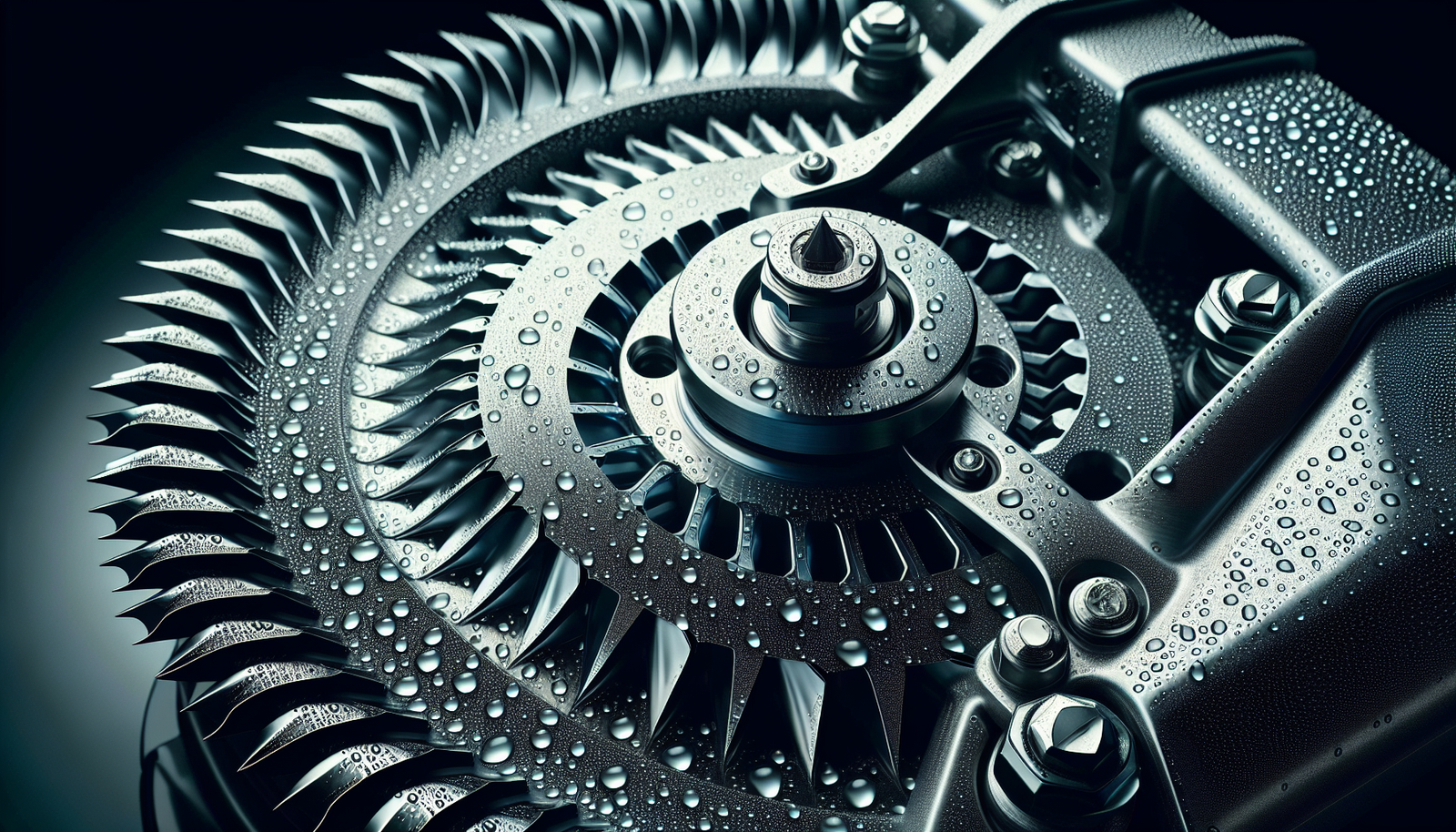

Toro lawn mowers incorporate cutting-edge features and technologies to enhance their functionality and user experience. Some common features include self-propulsion systems, precision cutting decks, adjustable cutting heights, and innovative blade designs for superior mulching and bagging. Additionally, Toro mowers often come equipped with advanced engine technology for improved fuel efficiency and reduced emissions.

Variants and Customization Options

Customers have the option to choose from various variants and customization options to suit their specific needs. Toro offers models with different cutting widths, engine options, transmission types, and additional features such as electric starts or bagging systems. This allows customers to find the perfect mower that aligns with their lawn size, terrain, and personal preferences.

Internal Production

Toro’s In-house Manufacturing Capabilities

Toro prides itself on its in-house manufacturing capabilities, allowing the company to have greater control over the quality and performance of their products. They have dedicated facilities and teams focused on producing various components, such as cutting decks, engine parts, drivetrain components, and more. By manufacturing these critical components internally, Toro can ensure consistent quality and compatibility across their product range.

Components Manufactured by Toro

Toro manufactures a wide range of components for their lawn mowers. These include cutting decks, which are designed and manufactured to deliver precise and even cutting performance. They also produce engine parts, such as pistons, cylinders, and carburetors, ensuring optimal performance and durability. Additionally, Toro manufactures drivetrain components like transmissions and axles, which are crucial for the mower’s maneuverability and efficiency.

Quality Control and Testing

Toro places a strong emphasis on quality control throughout the manufacturing process. Every component undergoes rigorous inspection and testing to ensure that it meets the company’s strict quality standards. From material selection to final assembly, Toro’s quality control processes help identify any potential issues early on, ensuring that customers receive reliable, long-lasting products.

Outsourced Production

Outsourcing Partnerships and Collaborations

In addition to in-house manufacturing, Toro also collaborates with external suppliers for certain components and parts. These outsourcing partnerships allow Toro to leverage specialized expertise and capabilities while maintaining their commitment to quality. Toro carefully selects and works closely with trusted suppliers, ensuring that all outsourced components meet their strict specifications and quality standards.

Components Sourced from External Suppliers

While Toro manufactures many components internally, there are certain components that are sourced from external suppliers. These may include specialized engine parts, electronic components, tires, or other specific components that require specialized manufacturing processes. Toro maintains close relationships with these suppliers, ensuring mutual collaboration and adherence to their quality standards.

Toro’s Quality Standards for Outsourced Products

Outsourced components undergo the same stringent quality control processes as internally manufactured parts. Toro maintains strict quality standards for all their products, whether they are produced in-house or outsourced. Through thorough testing, inspection, and collaboration with suppliers, Toro ensures that outsourced components seamlessly integrate with their products, delivering the same level of quality and performance expected from the Toro brand.

Assembly Process

Overview of Toro Mower Assembly

Toro’s assembly process is a crucial stage in the production of their lawn mowers. After individual components are manufactured or sourced, they are brought together in assembly facilities where skilled technicians meticulously assemble the mowers. The assembly process involves precision fitting of components, installation of engines and drivetrains, and various adjustments and calibrations to ensure optimal performance and functionality.

Key Assembly Facilities

Toro has dedicated assembly facilities equipped with advanced tools and equipment to facilitate efficient and precise mower assembly. These facilities are staffed with highly trained technicians who follow standardized assembly procedures to ensure consistency and quality. By centralizing assembly operations, Toro can maintain greater control over the manufacturing process and maintain their commitment to delivering reliable and durable lawn mowers.

Efficiency and Quality Control in Assembly

Efficiency is a key focus in Toro’s assembly process. The company implements lean manufacturing principles to optimize workflow and eliminate waste, ensuring that assembly operations are efficient and cost-effective. Furthermore, quality control is paramount throughout the assembly process. Each mower undergoes thorough testing and inspection to detect and address any potential issues before it leaves the assembly line, guaranteeing that customers receive products of the highest quality.

Research and Development

Importance of R&D for Toro

Research and Development (R&D) play a pivotal role in Toro’s continuous growth and success. The company recognizes the significance of staying at the forefront of innovation to meet evolving customer demands and technological advancements. Through R&D, Toro invests in new technologies, materials, and designs to improve their products’ performance, efficiency, and sustainability. This ongoing commitment to innovation enables Toro to deliver cutting-edge solutions to their customers.

Toro’s Approach to Innovation

Toro’s approach to innovation involves collaboration with industry experts, academic institutions, and customers. By partnering with leading researchers and institutions, Toro gains access to specialized knowledge and resources, allowing them to push the boundaries of technological advancements. Additionally, Toro actively seeks feedback and insights from their customers to understand their evolving needs and preferences, incorporating these insights into their R&D efforts.

Technologies and Improvements in Development

Toro’s R&D efforts are focused on developing technologies and improvements that enhance the performance, efficiency, and user experience of their lawn mowers. This includes advancements in engine technology for improved fuel efficiency and reduced emissions, integration of smart technologies for enhanced functionality and convenience, and advancements in cutting systems for superior performance and precision. By continually investing in R&D, Toro ensures that their products remain at the forefront of innovation in the industry.

Environmental Initiatives

Toro’s Commitment to Sustainability

Toro recognizes its responsibility to minimize its environmental impact and is committed to sustainable practices across its manufacturing operations. The company strives to reduce waste, conserve resources, and minimize emissions throughout its production processes. Toro’s commitment to sustainability extends beyond its manufacturing operations and also encompasses its product development, transportation, and post-consumer activities.

Green Manufacturing Practices

Toro has implemented various green manufacturing practices to reduce their environmental footprint. These practices include optimizing energy usage, implementing efficient waste management systems, and using recycled materials wherever possible. Toro also focuses on reducing water consumption in their manufacturing facilities, utilizing water-efficient processes and technologies to minimize waste and conserve this valuable resource.

Impact of Toro Mowers on the Environment

Toro is dedicated to developing and manufacturing lawn mowers that are environmentally friendly. They prioritize fuel efficiency, reducing emissions by incorporating advanced engine technologies that comply with strict emission standards. Additionally, Toro’s focus on precision cutting and mulching helps minimize waste, promoting healthy and sustainable lawn care practices. By using a Toro mower, customers can contribute to a cleaner and greener environment while maintaining beautiful lawns.

Customers’ Role in Production

Customer Feedback and Input

Toro values customer feedback and recognizes its importance in driving product innovation and improvement. The company actively encourages customers to provide feedback on their products, services, and overall experience. This feedback is invaluable in identifying areas for improvement, refining existing products, and developing new solutions that meet customer needs effectively.

Customization Options for Customers

To cater to individual customer preferences, Toro offers various customization options for their lawn mowers. Customers can choose from different configurations, features, and accessories to tailor the mower to their specific requirements. This level of customization ensures that customers can find a Toro mower that perfectly aligns with their unique needs and preferences, enhancing their overall lawn care experience.

Toro’s Customer Satisfaction Focus

Toro places a strong emphasis on customer satisfaction throughout the entire production process. From product design to manufacturing and after-sales service, Toro is dedicated to delivering exceptional customer experiences. The company’s commitment to quality, innovation, and customization options ensures that customers receive reliable and high-performing products that meet or exceed their expectations. By prioritizing customer satisfaction, Toro aims to establish long-lasting relationships with their valued customers.

Future of Toro’s Manufacturing

Toro’s Vision and Strategy

Toro’s vision for the future is to continue innovating and providing industry-leading outdoor equipment and turf maintenance products. They aim to be at the forefront of technological advancements and market trends, adapting to the changing needs and preferences of their customers. Toro’s strategy revolves around continuous investment in research and development, strategic collaborations, and sustainable manufacturing practices.

Adapting to Technological Advancements

As technology continues to advance at a rapid pace, Toro is committed to adapting and incorporating these advancements into their manufacturing processes and product offerings. This includes embracing smart technologies, internet connectivity, and automation to enhance the functionality and performance of their lawn mowers. By staying ahead of the technological curve, Toro can continue to offer cutting-edge solutions to their customers.

Anticipated Changes in Production

Toro anticipates several changes in the future of their manufacturing operations. These changes include increased reliance on automation and robotics to improve efficiency and reduce costs. Additionally, advancements in materials and manufacturing techniques may lead to lightweight and environmentally friendly mower designs. Toro will also continue to explore sustainable practices, such as using renewable energy sources and further reducing waste, to ensure their manufacturing processes align with their commitment to sustainability.

In conclusion, Toro’s history, commitment to quality, diverse manufacturing facilities, and focus on innovation and customer satisfaction position them as a leading manufacturer of lawn mowers. Their in-house manufacturing capabilities, along with strong partnerships with external suppliers, ensure that every component meets their strict quality standards. Through their efficient assembly processes, Toro delivers high-performance mowers that contribute to a cleaner and greener environment. With a focus on research and development, Toro remains at the forefront of innovation, continually improving their products and manufacturing processes. Looking to the future, Toro envisions adapting to technological advancements while maintaining their commitment to sustainability and customer satisfaction.