In the video, James Condon takes on the challenge of inspecting and cleaning a carburetor that is preventing a lawn mower from starting up. The owner of the lawn mower had upgraded to an electric mower and offered his old Toro Recycler for free. James outlines his process of diagnosing and fixing the issue, from checking the oil and fuel levels to testing the ignition and removing, cleaning, and reinstalling the carburetor. Ultimately, the repairs were successful, and the mower started and ran well. James also identifies a potential fuel leak from the tank, which was subsequently fixed by installing a new tank. Overall, the condition of the mower improved significantly after the repairs were made.

Inspecting the Lawn Mower

Initial assessment of the lawn mower

When you first receive a lawn mower that won’t start, it’s important to conduct an initial assessment to identify potential issues. In this case, the owner of the Toro Recycler mower suspected that a carburetor clean might solve the problem. However, it’s always best to conduct a thorough inspection to ensure that there are no other underlying issues causing the mower to malfunction.

Checking the oil and fuel levels

Before diving into the troubleshooting process, it’s crucial to check the oil and fuel levels in the lawn mower. This not only ensures that the mower has the necessary lubrication for its engine but also helps determine if there are any leaks or issues with the fuel system. In the case of the Toro Recycler mower, the oil level was checked and found to be sufficient. The fuel level was also checked, and although there was fuel in the tank, there seemed to be a slight issue with the fuel cap, which appeared to be loose.

Inspecting the blade and blade adapter

Another important step in the inspection process is checking the blade and blade adapter of the lawn mower. A bent or damaged blade can significantly affect the mower’s performance and may cause it to not start or work properly. In the case of the Toro Recycler mower, the blade and blade adapter were inspected and found to be in good condition, with only minimal wear. However, it was noted that the blade may need to be sharpened or replaced in the future.

Testing the engine for spark

To diagnose any potential issues with the ignition system, it’s essential to test the engine for spark. A strong spark indicates that the ignition system is functioning correctly, while a weak or nonexistent spark can be an indication of ignition problems. In the case of the Toro Recycler mower, the engine was tested for spark and found to have a strong spark, suggesting that the ignition system was not the cause of the starting issue.

Testing the ignition with starting fluid

One final step before moving on to more in-depth troubleshooting is testing the ignition system with starting fluid. Starting fluid is a quick and effective way to determine if fuel is reaching the engine and if the ignition system is working correctly. In the case of the Toro Recycler mower, starting fluid was used, and the engine successfully started, indicating that the fuel system may be the culprit behind the starting issue.

Cleaning the Carburetor

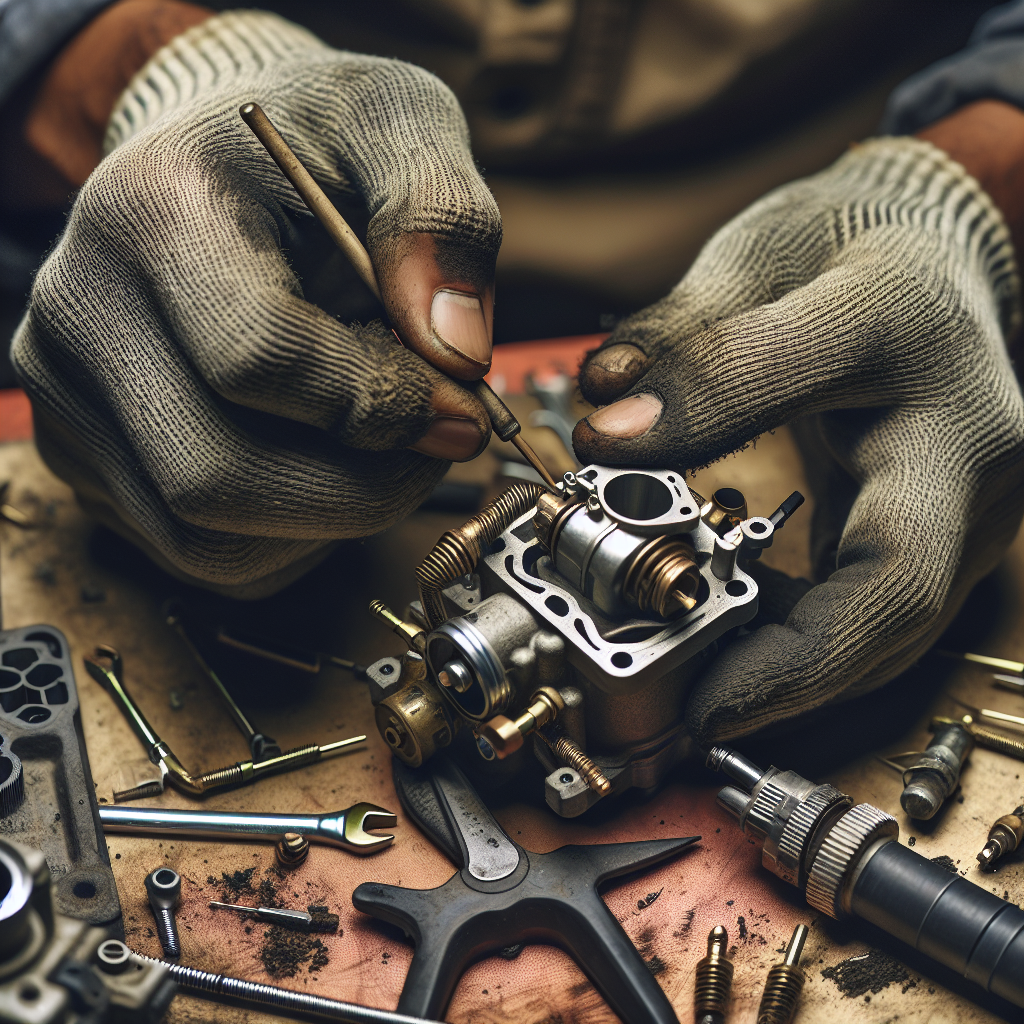

Removing the carburetor

With the preliminary inspection complete and the potential issue identified as a fuel system problem, it’s time to move on to cleaning the carburetor. Before cleaning the carburetor, it must be removed from the lawn mower. In the case of the Toro Recycler mower, the carburetor was removed by disconnecting the necessary tubes and fuel lines to access it.

Cleaning the carburetor

Once the carburetor is removed, it’s essential to thoroughly clean it to remove any dirt, debris, or clogs that may be affecting its performance. Cleaning the carburetor helps improve fuel flow, ensuring that the engine receives the proper fuel-to-air mixture. In the case of the Toro Recycler mower, the carburetor was cleaned using carburetor cleaner and a small brush to scrub away any buildup.

Inspecting the carburetor for clogs or issues

After cleaning the carburetor, it’s important to inspect it for any remaining clogs or issues that may have caused the starting problem. Closely examine the various components of the carburetor, such as the needle and seat, main jet, emulsion tube, and pilot jet. In the case of the Toro Recycler mower, the carburetor was inspected, and no clogs or issues were found. It appeared to be in good condition, indicating that the cleaning process resolved the fuel system problem.

Reinstalling the carburetor

Once the carburetor has been cleaned and inspected, it can be reinstalled back into the lawn mower. Ensure that all tubes and fuel lines are properly connected, and the carburetor is securely fastened to prevent any leaks or malfunctions. In the case of the Toro Recycler mower, the carburetor was reinstalled following the manufacturer’s guidelines and recommendations.

Testing the mower after carburetor cleaning

After reinstalling the carburetor, it’s crucial to test the lawn mower to see if the cleaning process resolved the starting issue. Attempt to start the mower and observe its performance. In the case of the Toro Recycler mower, it started successfully and ran well, indicating that the cleaning process effectively resolved the fuel system problem.

Identifying and Fixing Fuel Leak

Identifying a potential fuel leak

During the inspection process, it’s important to check for any potential fuel leaks in the lawn mower. A fuel leak can not only be dangerous but can also prevent the mower from starting or running properly. Look for any signs of fuel leakage, such as puddles or strong fuel odors. In the case of the Toro Recycler mower, a potential fuel leak was identified, which required further investigation and repair.

Inspecting the tank for cracks and distortions

To identify the source of the fuel leak, it’s necessary to closely inspect the fuel tank for any cracks, distortions, or other visible damage. Carefully examine the tank for any signs of wear or corrosion that may be causing the leak. In the case of the Toro Recycler mower, a crack and distortion were found in the tank opening, indicating that the fuel leak was likely originating from this area.

Ordering a new tank

Once the source of the fuel leak has been identified, it’s important to order a replacement tank to fix the issue. Contact the manufacturer or a reputable supplier to ensure you obtain the correct tank for your specific mower model. In the case of the Toro Recycler mower, a new tank was ordered to replace the damaged one.

Installing the new tank

After receiving the new tank, carefully follow the manufacturer’s instructions to install it correctly. Take care to connect all necessary tubes and fuel lines securely to prevent any future leaks. In the case of the Toro Recycler mower, the new tank was installed, ensuring that all connections were properly made and tightened.

Testing the mower for leaks

Once the new tank is installed, it’s crucial to test the lawn mower for any signs of leaks. Fill the tank with fuel and closely observe the area around the tank and fuel lines during operation. If no leaks are detected, it indicates that the replacement tank and installation were successful. In the case of the Toro Recycler mower, testing was conducted after the new tank installation, and no signs of leaking were found.

Performing Additional Maintenance

Identifying any additional maintenance needs

After addressing the initial starting issue and fixing the fuel leak, it’s important to consider any additional maintenance needs that the lawn mower may have. This can include inspecting and replacing other components that may be worn or damaged, ensuring the overall performance and longevity of the mower. In the case of the Toro Recycler mower, it is recommended to inspect the air filter and blade and consider future maintenance requirements.

Replacing the air filter

The air filter is a critical component of the lawn mower’s engine, as it prevents dirt, debris, and other contaminants from entering the combustion chamber. Over time, the air filter can become clogged or worn, affecting the mower’s performance. It’s essential to regularly inspect and replace the air filter as necessary to ensure optimal operation. In the case of the Toro Recycler mower, considering the age of the mower and its previous starting issues, it may be a good idea to replace the air filter to maintain proper airflow and prevent future problems.

Replacing the blade

The mower blade is another essential component that may require replacement over time. A dull or damaged blade can result in an uneven cut or poor performance. Regularly inspect the blade for signs of wear or damage, such as cracks, nicks, or excessive wear. If necessary, replace the blade with a new one to ensure a clean and efficient cut. In the case of the Toro Recycler mower, the blade was found to have minimal wear during the initial inspection. However, it’s important to keep an eye on its condition and replace it if necessary in the future.

Considering future maintenance

As with any piece of machinery, regular maintenance is crucial for optimal performance and longevity. Consider creating a maintenance schedule for the lawn mower, including tasks such as oil changes, spark plug replacements, and overall inspections. This proactive approach will help identify and address any potential issues before they become more significant problems. In the case of the Toro Recycler mower, consistent maintenance can help extend its lifespan and prevent future starting or performance issues.

Conclusion

Overall, the inspection, troubleshooting, and repair process of the Toro Recycler lawn mower proved successful. With a thorough assessment of the initial starting issue, the identification of a fuel system problem, and the necessary repairs and maintenance, the mower was able to start and run smoothly. By following these steps and regularly maintaining the mower, owners can ensure its optimal performance and longevity for years to come. Remember to always prioritize safety and consult the manufacturer’s guidelines for specific maintenance and repair instructions.