Are you tired of your lawn mower constantly acting up? One of the most common culprits behind lawn mower issues is a faulty carburetor. This vital component is responsible for mixing air and fuel in the engine, and when it malfunctions, it can lead to poor performance or even engine failure. In this article, we will walk you through the steps to locate and troubleshoot your lawn mower carburetor, helping you get your trusty machine back up and running smoothly in no time. Say goodbye to frustrating mowing experiences and hello to a perfectly manicured lawn!

Understanding the Basics of a Lawn Mower Carburetor

What is a carburetor?

A carburetor is an essential component of a lawn mower’s engine. It is responsible for combining air and fuel in the right proportions to create a combustible mixture that powers the mower. The carburetor regulates the flow of fuel into the engine and ensures that it runs smoothly and efficiently.

Why is the carburetor important for a lawn mower?

The carburetor plays a crucial role in the overall performance of a lawn mower. It ensures that the engine receives the correct amount of fuel, allowing it to start easily and run smoothly. A properly functioning carburetor also helps maintain consistent power output, prevents engine stalls, and maximizes fuel efficiency.

Components of a lawn mower carburetor

A lawn mower carburetor consists of several key components that work together to regulate the flow of air and fuel. These include the float bowl, which holds the fuel, the float mechanism, which controls the fuel level, the throttle plate, which controls the airflow, and various jets and passages that ensure the proper mixture of air and fuel.

Identifying Symptoms of Carburetor Problems

Engine fails to start

One of the most common signs of a carburetor problem is when the engine fails to start. This can be due to a variety of issues, such as a clogged fuel jet or a faulty float mechanism. If you have checked other potential causes, such as a dead battery or a lack of spark, the carburetor may be the culprit.

Engine runs rough or stalls

If your lawn mower’s engine is running rough or stalling frequently, it could indicate a problem with the carburetor. Most often, this is caused by a clogged jet or passage, which prevents the proper mixture of air and fuel. It can also be caused by a faulty float or needle valve, resulting in an inconsistent fuel supply.

Loss of power

If you notice a decrease in power output from your lawn mower, the carburetor could be to blame. A clogged or dirty carburetor can restrict the flow of fuel, resulting in a loss of power during operation. Regular maintenance and cleaning can help prevent this issue.

Excessive fuel consumption

If your lawn mower is consuming more fuel than usual, it could be a sign of a carburetor problem. A carburetor that is not properly calibrated or is dirty can cause the engine to run rich, resulting in excessive fuel consumption. This can be addressed through proper cleaning, adjustment, or in some cases, replacement.

Locating the Lawn Mower Carburetor

Checking the owner’s manual

The first step in locating the lawn mower carburetor is to consult the owner’s manual. The manual will provide detailed instructions and diagrams specific to your mower model. It will guide you on where to find the carburetor and how to access it.

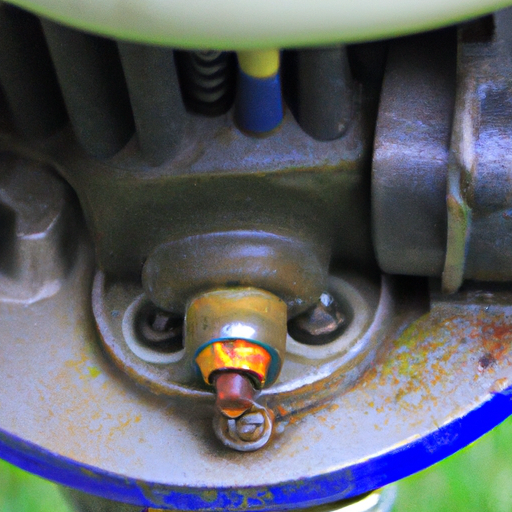

Inspecting the air filter housing

In many cases, the carburetor is located near the air filter housing. Inspect the housing and follow the intake hose or tube back to find the carburetor. It is often attached directly to the engine and can be easily identified by its venturi or choke plate.

Following the fuel line

Another way to locate the carburetor is by following the fuel line. Start from the fuel tank and trace the line until you reach the engine. The carburetor is typically connected to the engine through the fuel line. Look for a small metal or plastic unit with fuel line connections.

Removing the Lawn Mower Carburetor

Gathering necessary tools

Before removing the carburetor, gather the necessary tools. These may include a screwdriver, wrench, pliers, and a clean container to drain the fuel.

Draining fuel from the system

To prevent fuel spillage, start by draining the fuel from the system. Locate the fuel bowl drain screw or plug on the bottom of the carburetor and loosen it carefully. Allow the fuel to drain into the container until the carburetor is empty.

Disconnecting the fuel line

Next, disconnect the fuel line from the carburetor. Most fuel lines are connected using clamps or quick-release fittings. Use pliers or a wrench to loosen the clamp or release the fitting, and carefully remove the fuel line.

Detaching the carburetor

Once the fuel line is disconnected, the carburetor can be detached from the engine. It is usually held in place by screws or bolts. Loosen these fasteners and carefully remove the carburetor, being mindful of any attached gaskets or seals.

Cleaning and Repairing the Carburetor

Disassembling the carburetor

To clean and repair the carburetor, it needs to be disassembled. Carefully remove all the parts, making note of their position and order for reassembly. It is advisable to take pictures or label the parts to ensure proper reassembly.

Cleaning the carburetor

Use a carburetor cleaner or a dedicated carburetor cleaning solution to clean all the components. Pay special attention to the jets, passages, and float bowl. Ensure that all dirt, debris, and residue are removed. A small wire brush or toothbrush can be helpful for scrubbing hard-to-reach areas.

Inspecting and replacing damaged parts

While cleaning, inspect each component for signs of damage or wear. Look for cracks, corrosion, or excessive wear, particularly in gaskets, seals, and the float mechanism. Any damaged parts should be replaced with new ones to ensure proper functioning.

Reassembling the carburetor

Once all the parts are clean and inspected, reassemble the carburetor in the reverse order of disassembly. Ensure that all parts are properly aligned and tightened according to the manufacturer’s specifications. Double-check that gaskets and seals are correctly seated to prevent leaks.

Troubleshooting Common Carburetor Issues

Clogged fuel jets or passages

If your carburetor is clogged, the fuel jets or passages may be obstructed. Use a carburetor cleaner and a small wire or needle to clear any blockages. The cleaner helps dissolve the residue, while the wire or needle can carefully remove any debris.

Faulty float or needle valve

A faulty float or needle valve can result in inconsistent fuel supply and cause engine issues. Inspect these components for damage or wear. If necessary, replace them with new ones to restore proper fuel regulation.

Stuck or damaged throttle plate

If your engine is running at high idle or fails to return to idle smoothly, the throttle plate may be stuck or damaged. Clean the throttle plate and its housing with carburetor cleaner, and make sure it moves freely. If it is damaged, replace it with a new throttle plate.

Malfunctioning choke mechanism

A malfunctioning choke mechanism can cause difficulties in starting the engine or result in a rich air-fuel mixture. Check the choke for proper operation and cleanliness. If it is not functioning correctly, clean or replace it as necessary.

Adjusting the Lawn Mower Carburetor

Checking the manufacturer’s specifications

Before adjusting the carburetor, consult the manufacturer’s specifications for your mower model. These specifications will provide guidance on the correct settings for the carburetor, including idle speed and mixture adjustments.

Locating the adjustment screws

Most carburetors have idle speed and mixture adjustment screws. These screws are usually located on the side of the carburetor and can be adjusted using a screwdriver. The idle speed screw controls the engine’s idle RPM, while the mixture screws regulate the air-fuel ratio at different engine speeds.

Adjusting the idle speed

To adjust the idle speed, start the engine and let it warm up. Locate the idle speed screw and turn it clockwise to increase the RPM or counterclockwise to decrease it. Aim for a smooth and steady idle that keeps the engine running without stalling.

Fine-tuning the mixture

Fine-tuning the air-fuel mixture is done by adjusting the mixture screws. Start by turning the screws all the way in until they gently seat, and then back them out to the recommended number of turns specified in the manual. Adjust each screw equally until the engine runs smoothly at full throttle.

Reinstalling the Lawn Mower Carburetor

Attaching the carburetor to the engine

Once the carburetor is clean and adjusted, it can be reattached to the engine. Position the carburetor in place, aligning it with the mounting holes or studs on the engine. Tighten the screws or bolts securely to ensure a proper seal.

Connecting the fuel line

Reconnect the fuel line to the carburetor, making sure it is securely attached. Use pliers or a wrench to tighten any clamps or fittings as necessary. Ensure that there are no leaks or loose connections.

Refilling the fuel tank

With the carburetor reinstalled and the fuel line connected, refill the fuel tank with clean and fresh fuel. It is important to use fuel that is free from contaminants or stale, as this can affect the performance of the carburetor and engine.

Testing the mower’s operation

Start the lawn mower and observe its operation. Ensure that it starts easily, runs smoothly, and responds well to throttle adjustments. Check for any unusual noises or vibrations. If everything is working properly, you have successfully reinstalled the carburetor.

Preventive Maintenance for a Lawn Mower Carburetor

Regularly clean and inspect the carburetor

To prevent carburetor issues, it is essential to regularly clean and inspect it. This ensures that any dirt, debris, or residue does not accumulate and cause problems. Follow the manufacturer’s recommendations for cleaning intervals and use appropriate cleaning solutions.

Use clean and fresh fuel

Using clean and fresh fuel is crucial for the optimal performance of a lawn mower carburetor. Avoid using stale or contaminated fuel, as it can lead to clogs and malfunctions. Additionally, consider using fuel additives or stabilizers to help keep the carburetor and fuel system clean.

Add fuel stabilizer when storing the mower

When storing your lawn mower for an extended period, it is recommended to add a fuel stabilizer to the tank. This helps prevent fuel degradation and the formation of varnish or gum in the carburetor. Follow the manufacturer’s instructions for the proper amount of stabilizer to use.

When to Seek Professional Help

Persistent carburetor problems

If you have repeatedly encountered carburetor issues despite your best efforts to clean and repair it, it may be time to seek professional help. A certified technician will have the expertise and specialized tools to diagnose and resolve complex carburetor problems.

Lack of experience or expertise

If you are unfamiliar with carburetor systems or lack the necessary experience, it is advisable to entrust the repair and adjustment to a professional. Attempting to fix or adjust a carburetor without the necessary knowledge can potentially cause further damage or safety hazards.

Warranty coverage

If your lawn mower is still under warranty, it is recommended to consult the manufacturer or an authorized service center for any carburetor issues. Attempting to repair or modify the carburetor yourself could void the warranty. Take advantage of the warranty coverage to ensure proper repairs and replacements are done.

In conclusion, understanding the basics of a lawn mower carburetor and knowing how to identify and troubleshoot common issues is essential for maintaining a well-functioning mower. With regular cleaning, inspection, and proper adjustments, you can ensure that your lawn mower carburetor operates smoothly, providing reliable performance and longevity. Remember to seek professional help when needed and follow preventative maintenance practices to keep your carburetor in optimal condition.